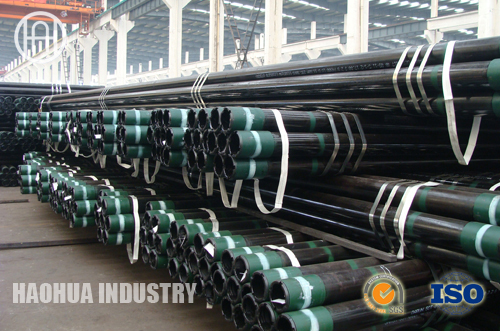

Section: Seamless and Welded

Standards:

API 5CT Specification for Casing and Tubing

ISO 11960:2004,Petroleum and natural gas industries-Steel pipes for use as casing tubing for wells

Sizes: Outside Diameter: 1.660"-30"

Grades: H40,J55,K55,N80,N80Q,L80,C90,C95,T95,P110,Q125,SS95,SS110,9%CR,13%CR

Some of the OCTG casing tubing available for your company’s requirements include:

General drill pipes,casing tubing conforming to API standards for oil field and deep well drilling

API H40 casing tubing – general purpose pipes conforming to API specification 5CT

API J55 general purpose pipes for casing tubing applications,similar to specification K55 with lower minimum tensile strength conforming to API specification 5CT

API K55 general purpose pipes used primarily in casings conforming to API specification 5CT

API L80 casing tubing conforming to API specification 5CT with a controlled yield strength with hardness test requirement of 23 HRC maximum; usually used in wells with sour (H2S) environments or deep sour wells

API N80 or N80 Q&T (Quench and Tempered) – general purpose pipe manufactured to API specification 5CT

API Normalized N80 – lower-cost alternative to standard Q&T N80; pipe walls less than 0.500 inch; inspections,testing and dimensions are in accordance with API 5CT for grade N80. Charpy v-notch impact test absorbed energy results conform to API SR16 and are lower Q&T N80

API C90 – an API controlled yield strength grade (25.4 HRC maximum) generally used in sour condensate wells; with required extensive hardness testing,SSCC testing per NACE Standard TM-0177-Method A; minimum threshold stress required is 80% of specified minimum yield strength

API C95 – same strength range as T95 and U. S. Steel C95,but without a hardness requirement; generally not used in sour wells

API T95 – API controlled yield strength grade (25.4 HRC maximum),the same as API C95 and U. S. Steel C95; generally for use in sour condensate wells; extensive hardness testing is required including SSCC testing per NACE Standard TM-0177-Method A; minimum threshold stress required is 80% of specified minimum yield strength

API P110 – generally used in deep wells; this grade is not suitable for most sour condensate wells

API Q125 – API grade for deep well service,generally not for use in sour condensate wells; quadrant hardness testing is required (no specified hardness limits other than the variation between readings); impact testing required for each heat and/or lot; typically EMI and UT NDT inspections are required

Connections:

STC (short round thread casing)

LTC (long round thread casing)

BTC (buttress thread casing)

XL (extreme-line casing)

Premium Connections

VAM,VAMTOP,NEW VAM

And almost any premium & gas tight connection

Length: Range 1,Range 2 & Range 3:

Applicable Tests: See our Standard Inspection Scope

Protection:

External bare and uncoated or externally coated with black/ transparent anti rust Mill varnish

Plastic or Metal Pin and Box Protectors.

Internal plastic coating or sleeves.

Mill Test Certificates:

Issued in accordance with API Specification 5CT Eighth Edition

Additional Third Party Inspection can also be performed on request.

High Collapse Casing and Tubing for Deep Well Service

Introduction:

High Collapse Casing and Tubing for Deep Well Service are seamless tubes designed to withstand high external pressures in deep oil and gas wells. These High Collapse Casing and Tubing are specially manufactured such that they have improved collapse properties, well in excess of API requirements.

The external pressure on the casing is directly proportional to the depth of the well. Hence, casings in deep wells are required to sustain high internal pressures, tension loads, and collapse pressures.

Grade and Mechanical Properties:

|

Grade |

Yield Strength (Ksi) |

Tensile Strength (Ksi) |

|

80ksi |

80-110 |

100 min |

|

95ksi |

95-125 |

110 min |

|

110ksi |

110-140 |

125 min |

|

125ksi |

125-150 |

135 min |

Size Range:

Outer Diameter: 4-1/2 inch – 13-3/8 inch

Thickness: 5.21 mm – 15.88 mm

Advantages:

Unique Production Technique: The material for high collapse casing and tubing is carefully selected to insure structural homogeneity. Strict control of heat treatment and dimensional tolerance is adhered to throughout the manufacturing process

Rigid Dimensional Control: Dimensional tolerances, such as roundness, straightness, outer diameter and wall thickness are strictly controlled.

Specified Collapse Value: A collapse test is carried out on each production run of high collapse casing and tubing with the same frequency as the tensile test.

Ensuring High Collapse Properties:

The collapse properties of the casings are directly related to the dimensional parameters of the tube (in turn a function of the tube rolling process), and the material properties of the tube (a function

of the quality of the steel and the heat-treat process of the tube). In order to guarantee the collapse properties of the casings, and to ensure consistency of these properties across batches, we maintain strict control over the entire production process, right from the melting of steel, the rolling of the tubes, to the quench & temper of the tubes. All the steel that is used for making high collapse casings is ladle refined and vacuum degassed to ensure a clean, inclusion free steel. Tube rolling parameters are tightly controlled so that ovality eccentricity, and wall thickness variation, factors that are detrimental to collapse, are minimized. Each tube is then carefully checked to ensure conformance with specifications.

Process Control:

To control strictly the inclusions in steel via the purity steel melting technology.

To control strictly the wall thickness and ovality of the tubes during the hot rolling.

To guarantee the yield strength and surface quality through the temperature and atmosphere control in the furnace during the heat treatment.

Through the second sizing and on line hot straightening after heat treatment, strictly control the residual stress, OD, ovality and straightness.

Collapse resistance: The minimum guaranteed collapse pressures are available on request.

Pipe inspection: A full length non destructive inspection is performed in accordance with API 5CT for external and internal, longitudinal and transverse defects with a standard notch depth equal to 5% of the specified wall thickness. The wall thickness is measured by ultrasonic method.

CASING AND TUBING FOR SOUR OIL AND GAS SERVICE

An unfavorable combination of H2S dissolved in water, low pH, susceptible structure and high loads, will cause cracks to occur in the steel pipe, which will propagate until failure occurs. Our SS grades are designed to prevent Sulfide Stress Corrosion Cracking (SSC) failures.

Casing and tubing for Sour Oil and Gas Service must have a good anti-SSCC (sulfide stress corrosion and cracking) performance in the environment where hydrogen sulfide corrosion exists. After an indepth study, we has successfully developed tubular goods of the Cr-Mo series for this purpose with good hardenability and tempering stability that when tempering takes places at certain temperatures uniform and fine sorbite structures can be obtained. Their mechanical properties can meet fully the requirements of corresponding grades and their anti-SSC performance is excellent by regulating the chemical composition and adopting different heat treatment procedures.

Grade and Mechanical Properties:

|

Grade |

Yield Strength (Ksi) |

Tensile Strength (Ksi) |

Hardness (HRC) |

Threshold Stress (SMYS) |

|

80ksiS |

80-95 |

95 min |

22 max |

85% min |

|

80ksiSS |

80-95 |

95 min |

22 max |

90% min |

|

90ksiS |

90-105 |

100 min |

24 max |

85% min |

|

90ksiSS |

90-105 |

100 min |

24 max |

90% min |

|

95ksiS |

95-110 |

105 min |

25 max |

85% min |

|

95ksiSS |

95-110 |

105 min |

25 max |

90% min |

|

100ksiSS |

100-115 |

110 min |

28 max |

85% min |

|

110ksiSS |

110-125 |

120 min |

30 max |

85% min |

|

125ksiSS |

125-140 |

130 min |

35 max |

85% min |

Size Range:

Outer Diameter: 4-1/2 inch – 13-3/8 inch

Thickness: 5.21 mm – 15.88 mm

Characteristics:

1. Materials: The chemical compositions have been carefully determined to provide resistance to sulfide stress corrosion as well as to insure complete through wall hardening.

2. Heat Treatment: Quenching and Tempering are conducted under rigid temperature control to assure homogeneous physical properties and microstructures.

3. Micro Structure: These grades exhibit fully tempered martensite which is considered to be the most desirable for resistance to sulfide stress corrosion cracking.

4. Tensile Properties and Hardness: Yield Strength is limited within a narrow range and hardness is controlled to within the predetermined maximum limit.

5. Sulfide Stress Cracking (SSC) Performance: Whole grades are designed for 85% or 90% SMYS in NACE condition. Excellent SSC resistance has been achieved through rigorous, chemical composition, heat treatment, microstructure, tensile properties, hardness and so on.

Pipe inspection:A full length non destructive inspection is performed in accordance with API 5CT for external and internal, longitudinal and transverse defects with a standard notch depth equal to 5% of the specified wall thickness.

API Spec 5CT Casing pipe And API SPEC 5L Line Pipe

API SPEC 5L is a international standard specifies requirements for the manufacture of two product specification levels (PSL 1 and PSL 2) of welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.

Related Products :

Threaded Casing with Short/Long Round Thread or Buttress

Drill Pipes with Welded-on Tool-Joints/Threaded End

Line Pipe with Plain End and Beveled

Boiler Tubes /Heat Exchanger Tubes

Carbon Steel Tubes for General Structural Purposes

Precision Carbon Steel Tubes

Seamless Tubing and Couplings Hydrosulfide-Carbon Dioxide- and Cold-Resistant

High Longevity Oil-Well Tubing and Interlocks of Production Strings for Corrosive Media

Wear-Resistant Tool Joints for Tubing

Seampless Tubing with Externally Upset Ends and Couplings Hydrosulfid- and Cold-Resistant

Drill Pipes with Welded Tool Joints

API Spec 5CT Casing pipe

Application:

Conveying gas,water,and oil in both the oil and natural industries, Tubular goods for petroleum and natural gas industries

Production Standard, Grade, Steel No:

API 5L PSL1 L175/A25, L210/A, L245/B, L290/X42, L320/X46, L360/X52, L485/X70, PSL2 L245R/BR, L290N/X42N, L320N/X46N, L360N/X52N, L415/X60N

API 5CT PSL1, PSL2, PSL3, H40, J55, K55, N80

Delivery Condition:

Annealed, Normalized, Normalized and Tempered

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness), Drift Test, Surface and Dimension Test,NDE, Hydrostatic Test, MT

Inspection and Tests Performed:

5L – Chemical composition, Mechanical properties, Hydrostatic test, Dimensional testing, Visual inspection, Nondestructive inspection

5CT – Chemical composition, Tensile test, Flattening test, Hardness test, Impact test, Grain size determination, Harden ability, Sulfide stress-cracking test, Hydrostatic test, Dimensional testing, Visual inspection, Non-destructive examination(NDE)

Surface Treatment:

5L – Uncoated(bare), Temporary coating, Special coating, Oil-dip, Shot Blasting, Varnish

Size: We supply various line pipes including seamless line pipes

(OD from 2-3/8" to 24", steel grade A, B, X42 - X80)